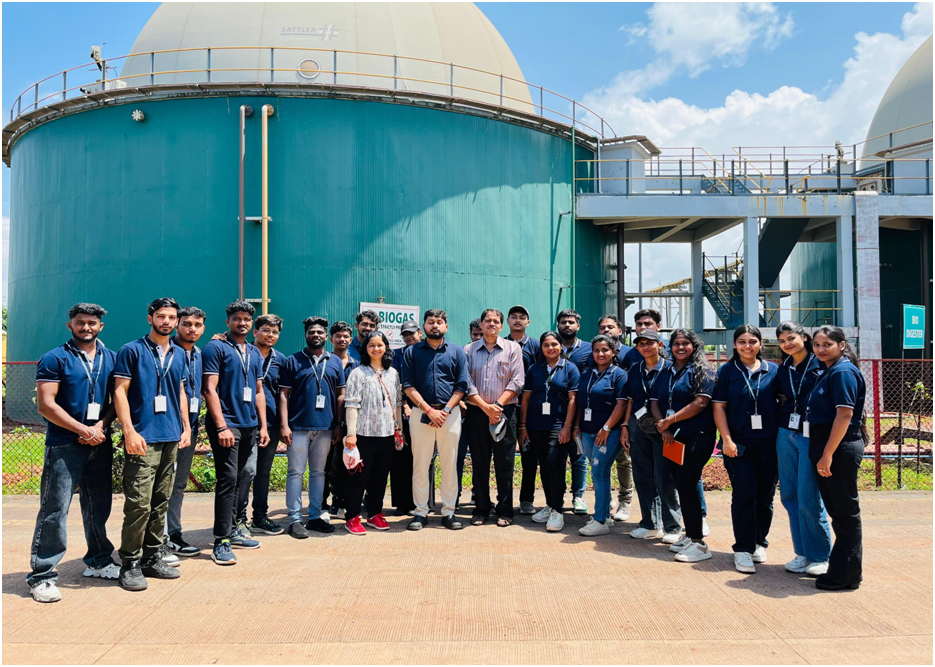

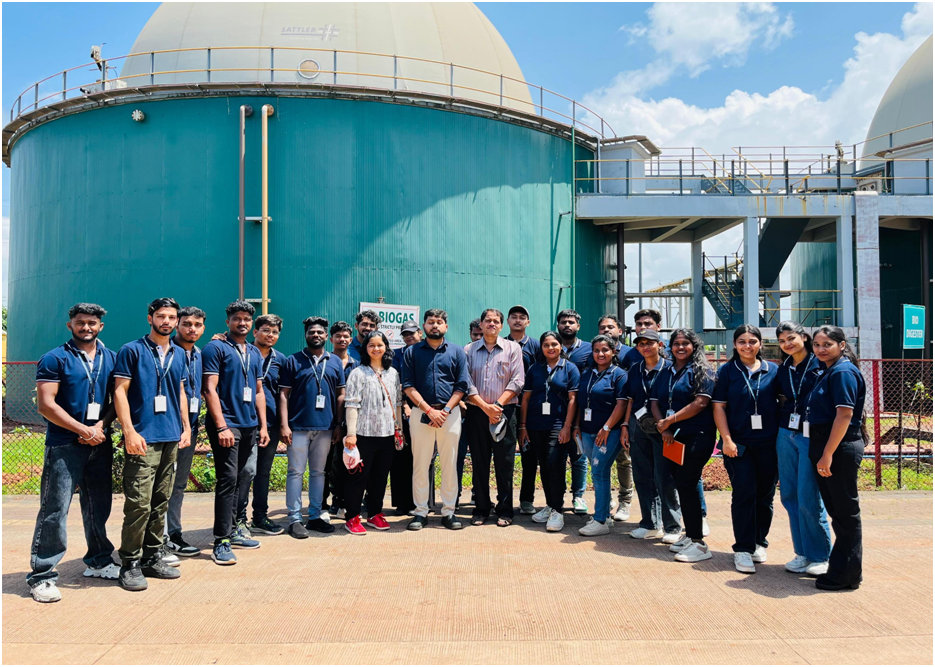

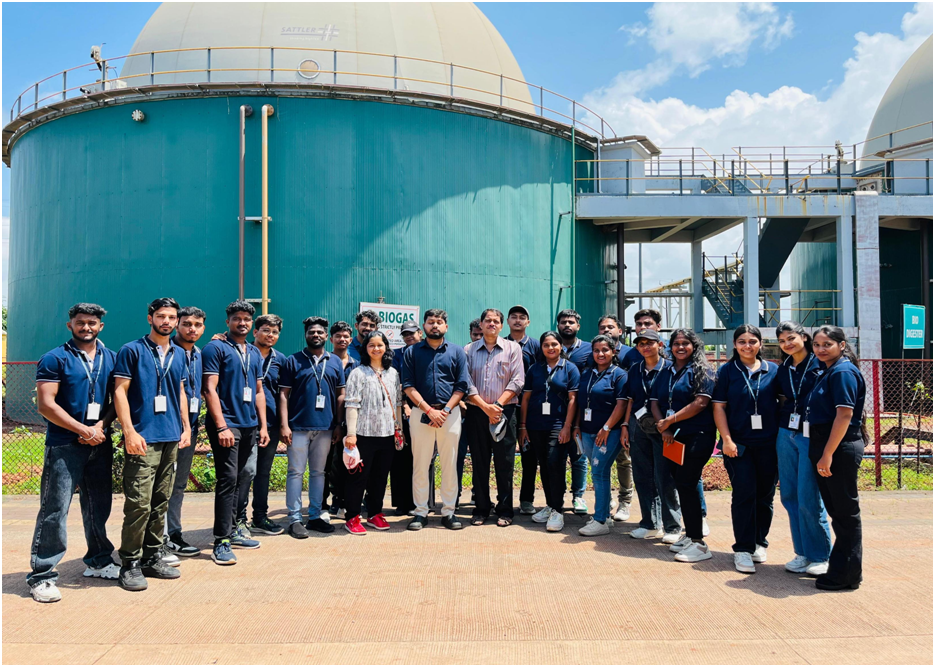

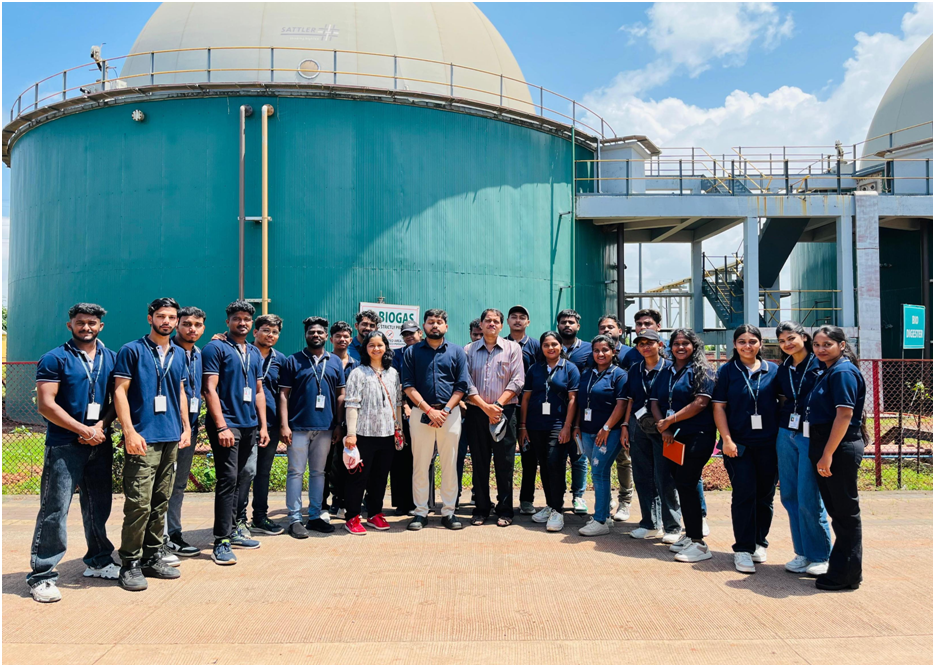

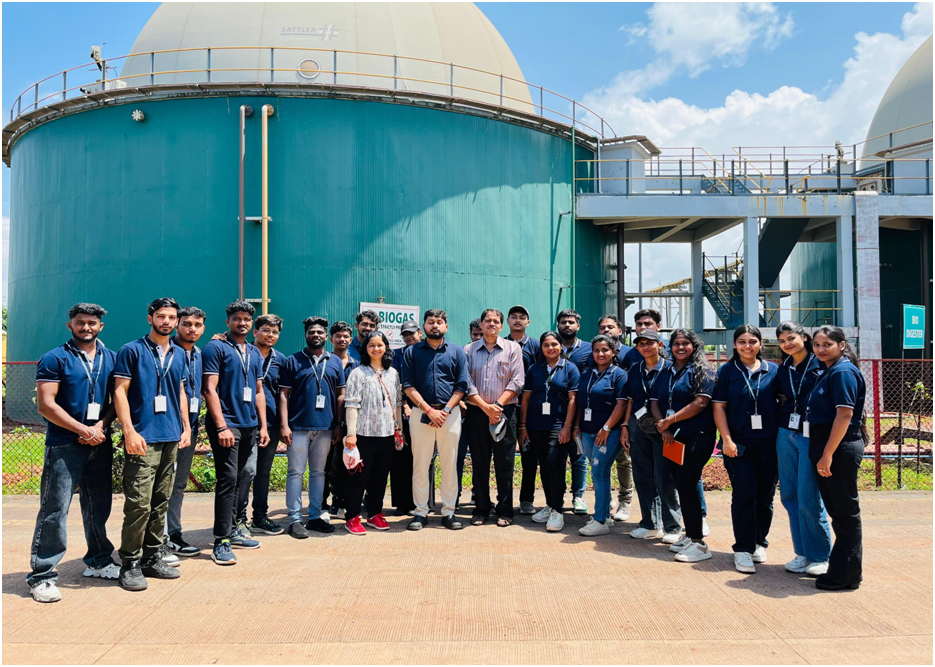

Industrial Visit Report

On

Goa Waste Management Corporation (GWMC) Goa

Introduction

MBA @ St. Philomena College (Autonomous), Mysuru, organized an industrial visit to the GWMC, Goa on 10/09/2025. The purpose of visit was to provide MBA students to reduce the gap of industry and academic.

Objective

- To familiarize students with the company’s activities and the waste management system.

- To get familiarize with the type of waste managed

- To get familiarize with waste collection system.

- To get familiarize with the process of waste management.

About the Industry

Goa Waste Management Corporation (GWMC) is a government organization responsible for collecting, segregating, and processing waste generated across different panchayats in Goa. It functions under the Department of Science, Technology and Waste Management, Government of Goa. The corporation plays a vital role in ensuring cleanliness, environmental protection, and promoting recycling and reuse practices.

Leadership

The corporation is overseen by senior leadership appointed by the Government of Goa:

Managing Director (MD): Shri. Harish Adconkar, GCS

Chairman: Dr. Pramod Sawant, Hon’ble Chief Minister of Goa

Vice Chairman: Shri. Atanasio Monserrate, Minister for Science & Technology & Waste Management

This leadership team is responsible for policy implementation, strategic decision-making, and ensuring that the organization’s activities are aligned with the state’s environmental goals.

Key Learnings from the Visit

Types of Waste Managed

- Waste is broadly divided into two categories: Dry Waste and Wet Waste.

- On average, the plant collects around 250 tonnes of waste per day:

• 100 tonnes – Dry waste

• 150 tonnes – Wet waste

Collection System

- Waste is collected from various panchayats across Goa.

- Proper segregation is carried out to separate recyclable materials.

Tetra Pack Processing

- Labourers manually separate tetra packs and other recyclable items. This process helps in efficient recycling and reuse.

Power Consumption

- The plant requires a total of 28,000 to 30,000 units of electricity. Out of this, 12,000 units are consumed by machinery used for segregation and processing.

Process of Waste Management at GWMC

During the visit, the students learnt about the step-by-step process of how waste is scientifically managed at the plant:

- Workshop Area – The waste first passes through a workshop area where initial activities and segregation take place.

- Wet Waste Handling – Wet waste is collected into bunkers where it is converted into pulp.

- Sewage Treatment Plant (STP) – The pulp is then transferred to an STP and stored in a biodigester.

- Boom Structure – The biodigester is maintained at an elevated temperature with the help of a boom structure.

- Biogas Generation – The plant operates three gas engines. Biogas generated is supplied for further treatment, while solid substances are separated.

- Solid–Liquid Separation – Waste is separated into solid and water substances.

- UF and RO Treatment – After treatment, Ultrafiltration (UF) is conducted followed by Reverse Osmosis (RO). RO-treated water is purified, while RO rejects are collected and disposed of properly.

- Sludge Drying – The solid sludge is transferred to a sludge drying area. Here, the sludge is dried for 3–4 days and mixed for further disposal or recycling.

Machinery and Technology

The GWMC plant is equipped with a range of machinery to handle large-scale waste processing:

- Segregation Machines: Used for efficiently separating dry and wet waste.

- Biogas Engines: Three engines are installed to convert biodegradable waste into useful biogas energy.

- RO & UF Treatment Units: Advanced filtration units help in treating wastewater effectively.

- Sludge Drying Beds: Machines and drying structures reduce moisture and prepare sludge for safe disposal.

- Boom Structures: These help in maintaining temperature during the biodigestion process.

The use of advanced technology highlights the corporation’s commitment to efficiency and sustainability.

Labour and Workforce

Despite mechanization, labour plays an essential role at GWMC. Workers are engaged in several activities:

- Manual Segregation: Workers carefully separate tetra packs, plastics, and recyclable materials.

Maintenance Support: Labourers assist in operating machinery, cleaning, and maintaining equipment. - Sludge Handling: Workers manage the drying and mixing of sludge in the drying area over 3–4 days.

- Workshop Operations: Skilled labourers are deployed in the workshop area for pre-processing tasks.

The combined efforts of machinery and human labour ensure the smooth operation of the facility.

Observations

- The process at GWMC is a well-structured combination of mechanization and manual labour.

- The biogas production and RO treatment reflect a focus on energy efficiency and recycling.

- The sludge drying process shows how even waste by-products are utilized effectively.

- The visit highlighted the challenges of high power consumption and the importance of community participation in segregation at source.

- The dedication of both management and workforce ensures the corporation achieves its goals effectively.

Conclusion

The industrial visit to Goa Waste Management Corporation was highly educational and insightful. It provided us with practical exposure to waste segregation, treatment, and recycling processes. As management students, we learned not only about operations and resource management but also about sustainable development practices. The leadership, machinery, and labour force together contribute to making GWMC a model for scientific waste management. The knowledge gained during this visit will help us understand the importance of effective waste management and inspire us to think about sustainable solutions in our future managerial careers.