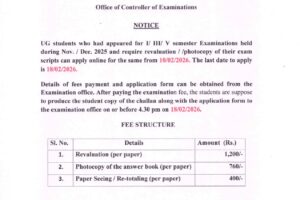

Industrial Visit Report

Date of Visit: 13/01/2025

Location of Visit: ShreeGluco Biotech Pvt. Ltd. Gejjiganahalli Village, T.Narasipura to Nanjungud Road, Nanjungud Taluk, Mysore District, Karnataka, India 571129.

Industry Sector:Manufacture, Market and Export the corn wet milling product and its derivatives.

Organized by: PG Dept. of Food Science and Nutrition, St Philomena’s College(Autonomous), Bannimantap, Mysuru 570 015.

Purpose of Visit: To gain practical insights into the operations, production processes and technologies used in industry and to understand how theoretical concepts are applied in a real-world industrial setting.

- Introduction

The industrial visit aimed to expose students to the operations of a leading company in corn processing at ShreeGluco Biotech Pvt. Ltd. The visit provided an opportunity to understand various stages of the production process, technological advancements, quality control and management practices that are crucial to the success of an industrial operation.

- Company Overview

ShreeGluco Biotech Pvt. Ltd. is a Karnataka Based company and was incorporated in Feb 2012 as a Private Limited Company under the Companies Act, 1956. It has established as a Maize Starch and its derivatives manufacturing unit in Nanjangud Taluk, Mysore District, Karnataka.The production at the company commenced in Jan 2018. ShreeGluco is the manufacturer and seller of high-quality maize starch and its derivatives for the use in various industries, including food, paper, adhesive, textile and construction industry. ShreeGluco Biotech Pvt (SGBPL) has a state of art corn wet milling plant incorporated since 2012. They manufacture the finest quality products of Maize Starch Powder, Liquid Glucose, Maltodextrin, Modified Starches and various other by-products. SGBPL is promoted by Mr. Srinath Bysani, who is a pioneer in Corn Trading for the last three decades. His vision of SGBPL is an outcome of forward integration from his trading business.The company has been a key playerfor 8 years and operates under the core values of innovation, qualityand sustainability.

- Key Areas Explored

Production Processes:

We were given a tour of the manufacturing/production facility, where we observed various stages of production.

- Corn Reception and Cleaning: The first stage of processing consists of receiving and cleaning the corn. During this phase, the grains are cleaned to remove impurities and foreign matter that could affect the final quality of the product.

- Corn Classification:Grading is a crucial step in maize processing. Corn is graded based on size, weight and quality to ensure uniformity in the final product. Grading equipment removes impurities, broken grains and grains of different sizes. It offers classification equipment such as rotating screens and vibrating screens that are essential for this step. This equipment guarantees a precise and efficient classification of corn grains, contributing to the quality of the final product.

- Corn Storage: Once sorted, corn needs to be stored properly to maintain its quality and freshness. Proper storage is crucial to prevent contamination of the corn and to ensure that it is in optimal condition for subsequent processing. The company offers a range of grain storage solutions including storage silos. These silos are designed to keep corn in optimal conditions, protecting it from adverse weather conditions and pests. In addition, they also offers grain transport systems, such as bucket elevators and screw conveyors, which facilitate the safe and efficient movement of corn from the storage location to the processing location.

- De-germination: De-germination is the process that removes the germ from corn. The germ is the part of the grain that, if allowed to germinate, would give rise to a new corn plant. Removing the germ is important because, although nutritious, the germ contains oils that can become rancid and compromise the quality of corn products during storage.

- Grinding and Making Grits: Grinding is the process of breaking corn kernels into smaller pieces known as grits. Grits are used in the production of various food products, such as breakfast cereals, snacks and beverages.

- Grit Rating: After grinding, the grits are sorted by size and shape. Grading allows grits to be used to produce different types of food products.

- Corn by-products and their processes: Corn processing also generates various by-products such as corn bran, corn oil and corn protein. These by-products are used in various industries, including food, feed and biofuels.

- Pre-Gel Corn – Gelatinized:

- Pregelatinized corn is a versatile food product that has undergone a pre-cooking and drying process, making it a widely used ingredient in many sectors of the food industry. The essence of this process is the gelatinization of the starch contained in the corn kernels (modified starch).

- Gelatinization occurs when starch is heated in the presence of water. During heating, starch molecules absorb water, swell and the crystalline structure of starch is destroyed, resulting in a viscous mass or gel. This process is interrupted by drying, fixing the starch structure in a gelatinized state.

- The result is a product that is able to absorb water and swell quickly, even at ambient or low temperatures, making it an ideal choice for foods that require quick preparation or thickening, such as instant soups, sauces, breakfast cereals, baked goods and others. Furthermore, gelatinization does not change the nutritional value of corn, so pre-gelatinized corn remains a rich source of carbohydrates, protein, fibre and a variety of vitamins and minerals.

Some of main corn processing equipment where the students were able to explore were:

- Grain cleaning machines: cleaning machines were designed to remove impurities and foreign material from corn kernels, ensuring that only high-quality kernels are processed.

- Degerming equipment: degerming solutions that efficiently separate the germ from the rest of the grain, allowing the production of by-products such as corn oil.

- Mills and flocculators: producing a variety of corn by-products, including grits and cornmeal. In addition, high-capacity flocculators are ideal for producing high-quality corn flakes.

- Sorting equipment: grading machines allow efficient selection of corn flakes and grits according to size, ensuring a consistent final product.

- Storage systems: robust and reliable storage solutions designed to maintain product quality during storage.

- Packing systems: packaging systems were designed to efficiently package end products while maintaining product quality and integrity.

Corn by-products

- Maize starch: Cornstarch is one of the most well-known by-products of corn. It is extracted from the endosperm of the corn kernel and is used in many industrial sectors, including the food industry (as a thickener in soups and sauces), the textile industry (in finishing fabrics) and the paper industry (as an adhesive in the production of cardboard).

- Corn Fibre: Corn fibre is a by-product of the corn milling process. It is used in the manufacture of animal feed, and has recently been exploited for the production of cellulosic ethanol, a type of biofuel.

- Corn Bran: Corn bran is a byproduct of corn milling and is primarily used as an ingredient in animal feed.

- Corn Syrup: Corn syrup is a liquid sweetener made from cornstarch. High fructose/Maltose corn syrup (HFCS/HMCS) is a common type of corn syrup used in many food and beverage products.

- Corn Germ: The corn germ is the embryo of the corn kernel, and this is where most of the corn oil is located. Corn germ is often used in the animal feed industry, but it can also be used to extract corn oil.

- Corn meal: Cornmeal is obtained by finely grinding corn kernels. It is widely used in the cuisine of various regions of the world. In Brazil, it is used in the preparation of dishes such as polenta and cornmeal cake. In addition, cornmeal is also used in the production of bread, cakes and cookies.

- Cornflour: Cornmeal is a little thicker than cornmeal and is made from dried and ground corn kernels. It is used in several recipes, such as cookies, cakes, pies and also in breads.

Technology and Automation &Quality Control:

The quality control department was an important stop on the tour. We were briefed on the methods and tools used to maintain high product standards, such as;

- Grain cleaning machines: cleaning machines were designed to remove impurities and foreign material from corn kernels, ensuring that only high-quality kernels are processed.

- Degerming equipment: degerming solutions that efficiently separate the germ from the rest of the grain, allowing the production of by-products such as corn oil.

- Mills and flocculators: producing a variety of corn by-products, including grits and cornmeal. In addition, our high-capacity flocculators are ideal for producing high-quality corn flakes.

- Sorting equipment: grading machines allow efficient selection of corn flakes and grits according to size, ensuring a consistent final product.

- Storage systems: robust and reliable storage solutions designed to maintain product quality during storage.

- Packing systems: packaging systems are designed to efficiently package end products while maintaining product quality and integrity.

Sustainability Initiatives:

The company has undertaken several eco-friendly initiatives to minimize environmental impact, such as; solar and biodiesel options.

Energy-consumption:

The operation of a maize milling plant requires a significant amount of energy, primarily for running the milling machines, conveyor belts, and other equipment. To minimize the environmental impact, the company focuses on energy-efficient technologies and equipment. Advanced milling machines were designed to optimize energy usage, reducing overall electricity consumption.

Water Consumption:

Water is also a vital resource in maize milling, used for cleaning, conditioning and separating grains. Excessive water usage can strain local water sources and harm ecosystems. Company relied on wells and river. By implementing these measures, they strive to conserve water resources and reduce environmental footprint.

Waste-management

The milling process generates various types of waste, such as husks, bran and stalks. Improper disposal can lead to soil degradation and contribute to land pollution. AtShreeGluco Biotech, they prioritize efficient waste management practices. By implementing recycling and composting techniques, they converted agricultural waste into valuable resources, such as organic fertilizers or animal feed. This approach minimizes waste sent to landfills and promotes sustainability.

Research & Development (R&D):

The visit also included an introduction to the R&D department, where innovations and future product developments were discussed. We were informed about the company’s investment in continuous innovation and market research to stay ahead in the industry.

- Learning Outcomes

Understanding Industrial Practices:

The visit provided a real-world perspective on industrial practices, bridging the gap between academic learning and industrial application.

Application of Theoretical Concepts:

Concepts from our academic curriculum such as production management, quality control, supply chain and automation were clearly demonstrated in the company’s operations.

Exposure to New Technologies:

The industrial visit helped the students understand the role of cutting-edge technologies in enhancing productivity and efficiency in modern industries.

Career Insights:

The students gained insights into potential career opportunities atShreeGlucoBiotech Pvt.Ltd. with professionals sharing their career journeys and advice for those interested in pursuing a similar path.

Faculty with student and industrial staff

- Conclusion

The industrial visit to ShreeGluco Biotech Pvt ltd was an enriching experience that enhanced our understanding of industrial processes and provided valuable insights into the corn industry operations. It was a perfect opportunity to see the practical application of the theories and concepts. The visit also emphasized the importance of technology, sustainability and innovation in shaping the future of industries.

Acknowledgement:

We would like to thank the management and staff of ShreeGlucoBiotech Pvt ltd for their time and for providing such an informative and engaging experience.

Recommendations for Future Visits:

- Longer duration for a more in-depth tour.

- More interaction with operational teams for a deeper understanding.

- Access to more technical workshops or demonstrations.

- This report serves as a summary of the industrial visit and reflects the key insights gained during the visit.