Industrial Visit to BEML

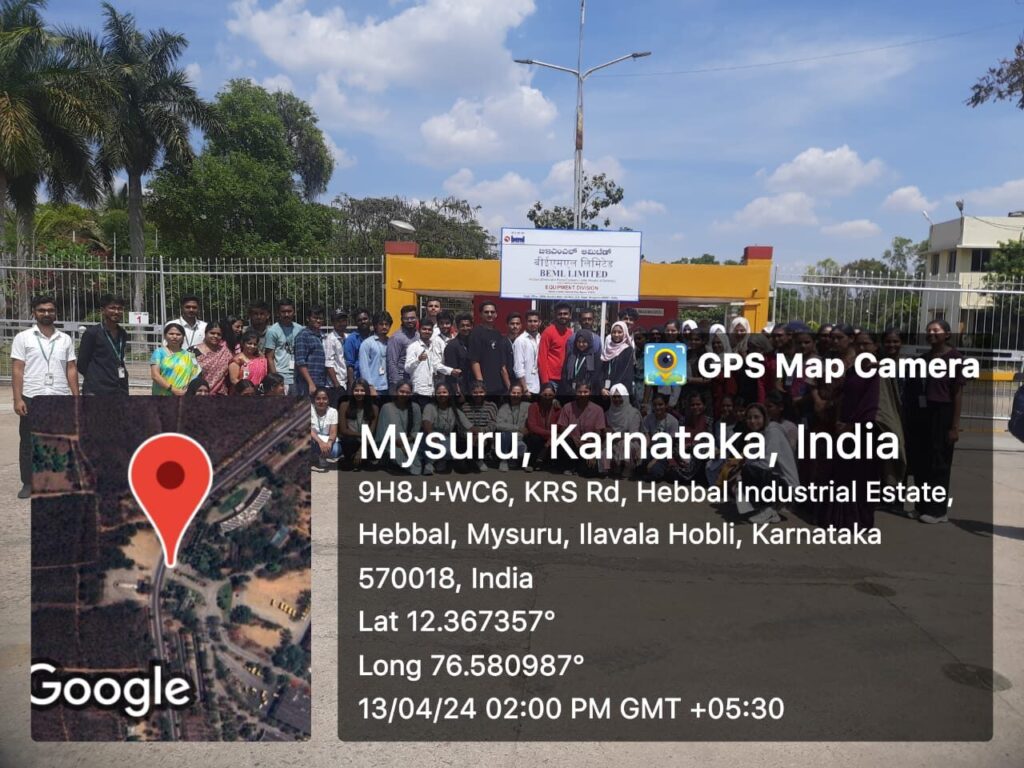

An industrial visit was conducted by Department of Computer Science , BCA and BSc to BEML Company, Mysore, on 13th of April 2024. The college bus was organized for 58 students and 6 staff members.The visit started from the college campus at 10:30am and reached BEML campus at 11:00am.

Firstly all the students were assembled in the seminar hall where they were given the brief introduction about the different machineries and heavy vehicles manufactured by BEML for defense.

BEML company branches are Bangalore, Kolar, Palkad and Mysore. In Mysore branch, basically there are divisions like Engine division and truck division.

BEML Company is specialized for manufacturing the heavy vehicles such as biggest dumpers, railway coaches, bulldozers, trucks. BEML Company has manufactured underground water sprinklers which are used in coal mines to reduce the dust. BEML is also known for manufacturing mobile bridges, bullet proof trucks, missiles carrying trucks, missile launching platforms. BEML production is now focused on tetra defense trucks used for carrying heavy missiles.

The vehicles manufactured in the company are having special features such as these vehicles can easily climb across terrains, wheel can be demobilized individually that means rear left wheel can be stopped completely without affecting the working of other wheels, safety cabins for drivers etc. The chief officer of BEML gave a inspiring talk to the students and asked student to design a computer that is useful to the people in different sectors.

After the brief introduction, students were divided into two groups and taken to the production section of the company by the field experts. In the beginning they took the students to storage section where different electrical components were organized in racks. Students were excited to see the wheel of around 12 feet high. For designing the blueprint of the machinery AutoCAD software is used.

Later they took the students to plate section, fabrication section ,machine section, then light weight assembly unit ( below 60 tons) and heavy weight assembly unit (above 60 to 1000 tons) and lastly to the testing unit where around 50 thousand to 60 thousand components are assembled together.

Students and staff members were very happy and astonished to see such a huge manufacturing unit where our country’s defense products are finally produced and assembled.